Silk foil volume stamping

All products are made to order.

More examples

Hide

More examples

Hide

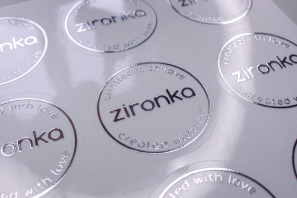

Innovative technology Silk Foil enables to obtain relief effects on printed products without embossing and without clichés.

Application of UV glue combined with metallized foil results in creation of raised elements sensible to the touch.

The principle of the technique is that glue is transferred through a stencil on the material. The glue is polymerized by UV lamps and then metallized foil is stamped onto the UV treated glue. Such relief printing can be applied almost on any materials: paper, faux leather, plastic, glass, wood.

UV glue creates 3D image with relief. It is possible to vary the height of the relief by making the layer of UV glue more or less thick.

Silk Foil technology has evident advantages over classic hot stamping: no need to pay for preparing clichés, extremely fine details with relief are possible. Even the most delicate elements and thin lines have a homogeneous, smooth and stable surface and edges, cost-effectiveness even for small quantities (for example, printing of wedding invitations).

This method allows not only to highlight by relief images, lines and decoration elements but to print text as well. For instance, text (name, contacts, logo) printed in Silk Foil technique on a visiting card made from ordinary cardboard (even not construction one) will make this card special.

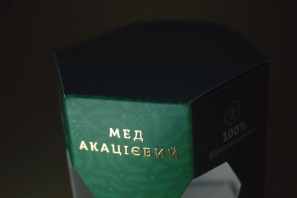

In order to maintain the quality of Silk Foil embossing, it is important to use high quality materials and manufacturing processes. It is also important to avoid mechanical damage during storage and transportation of the boxes. Silk Foil Volume Embossing is a decoration technique that uses a special foil material that gives images volume and shine. This method is used to create customized and exquisite boxes to order.

How do you maintain the quality of Silk Foil volume embossing on boxes?

What is Silk Foil Volume Embossing and how is it used to finish custom boxes to order?